Purpose:

This article delves into the definition, importance, and methods for detecting faults. It also covers making repairs for the crankshaft position sensor.

Introduction

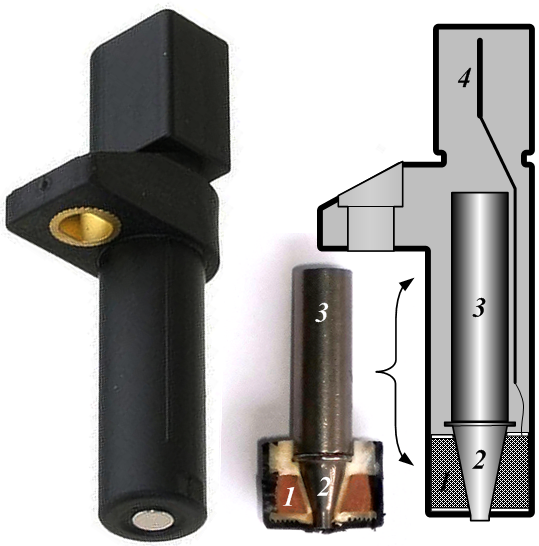

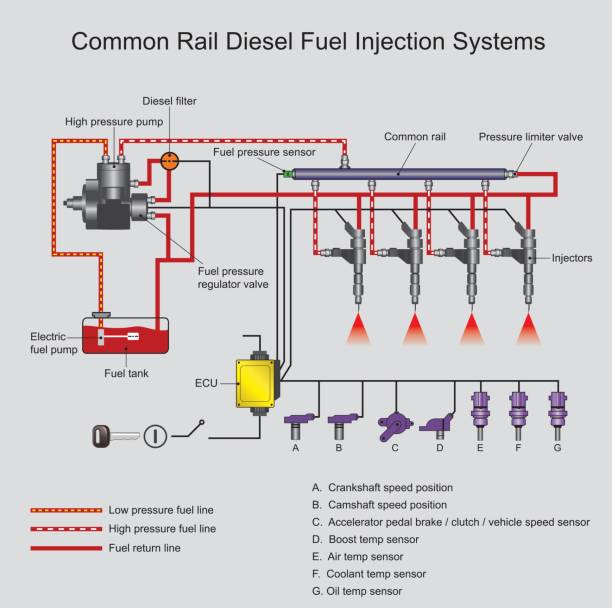

The crankshaft position sensor (CKP) is vital. It is part of the engine management system in cars. It is typically located near the crankshaft, either in the engine block or the cylinder head. The primary function of the CKP sensor is to monitor the rotational speed and position of the crankshaft. It is used for many engine functions include ignition timing, fuel injection, and transmission control.

The CKP sensor operates by detecting the precise position of the crankshaft as it rotates. It usually uses a magnet or Hall-effect sensor. These generate signals based on the position of teeth or protrusions on the crankshaft's flywheel or harmonic balancer. These signals are then processed by the engine control unit (ECU) to determine the crankshaft's speed and position.

Fault Detection:

Like other car parts, crankshaft position sensors wear out and fail over time. Finding faults in the CKP sensor is crucial. It keeps the engine running well and prevents breakdowns. Here are some common signs of a faulty crankshaft position sensor:

Engine Misfires: A broken CKP sensor can cause wild ignition timing. This can lead to engine misfires or hesitation during acceleration.

Stalling: If the CKP sensor fails to provide accurate data to the ECU, it may result in engine stalling, especially at low speeds or idle.

Difficulty Starting: A faulty CKP sensor can prevent the engine from starting. It can also cause long cranking before ignition.

Check Engine Light:The check engine light on the dashboard often indicates engine problems. This includes faults with the CKP sensor. Retrieving diagnostic trouble codes (DTCs) using an OBD-II scanner can pinpoint the exact nature of the problem.

Diagnostic Procedures:

Automotive technicians often diagnose CKP sensor faults. They follow steps to find the true cause. These may include:

Visual Inspection: Inspect the wiring harness, connectors, and sensor mounting location. Look for any signs of damage, corrosion, or loose connections.

Electrical Testing: Using a multimeter to measure the CKP sensor's electrical resistance and voltage output. Discrepancies from manufacturer specifications indicate a potential fault.

Signal Testing: Use an oscilloscope or scan tool to study the waveform of the CKP sensor signal. Do this while the engine is running. An irregular or inconsistent signal pattern may indicate sensor malfunction.

Code Retrieval:You will use an OBD-II scanner to retrieve diagnostic trouble codes (DTCs). These codes are stored in the ECU memory. Specific codes related to CKP sensor faults provide valuable diagnostic information.

Repair and Replacement:

If a faulty CKP sensor is diagnosed, it is essential to address the issue promptly to avoid further engine damage or performance issues. Depending on the severity of the fault, repair or replacement options may include:

Sensor Cleaning: In some cases, debris or oil contamination may affect the CKP sensor's performance. Cleaning the sensor and its mounting area can restore functionality.

Wiring Repairs:You must repair or replace damaged wiring harnesses, connectors, or terminals. They are associated with the CKP sensor. This fix will ensure proper electrical connectivity.

Sensor Replacement: If the CKP sensor is unfixable, replacing it with a new, OEM-quality sensor is often the best solution. Proper installation and calibration are crucial to ensure accurate operation.

ECU Reprogramming: In some cases, you may need to reprogram or update the engine control unit's software. This will fix CKP sensor issues, if they are caused by software glitches or compatibility issues.

Conclusion:

The crankshaft position sensor is vital for modern car engines. It plays a crucial role in engine management and performance. Knowing its function is key. Finding faults and doing necessary fixes are vital parts of car maintenance and repair. By using proper diagnostic procedures and fixing CKP sensor issues quickly, vehicle owners can ensure the engine works well and lasts a long time.