Introduction:

TPMS stands for Tire Pressure Monitoring System. It's a safety feature in modern vehicles designed to alert drivers when the air pressure in any of their tires drops to an unsafe level.

Tire pressure status

Recap history:According to estimates by the National Highway Traffic Safety Administration (NHTSA), without TPMS, there are approximately 23,000 traffic accidents related to tire leaks or blowouts each year in the United States, resulting in 535 fatalities. Both of these issues are likely caused by improper tire pressure. Due to safety concerns, the U.S. government enacted the Transportation Recall Enhancement, Accountability, and Documentation (TREAD) Act. As part of the TREAD Act, Federal Motor Vehicle Safety Standard (FMVSS) 138 mandates that all cars, trucks, and buses with a gross vehicle weight rating (GVWR) of 10,000 pounds or less, manufactured in small quantities, must be equipped with TPMS since 2008.

Situation in various countries:In other parts of the world, awareness of the safety issues associated with improper tire pressure has also been recognized. In France, Sécurité Routière estimates that 9% of traffic fatalities are caused by underinflated tires. In Germany, DEKRA estimates that tire-related issues account for approximately 41% of all traffic fatalities and points out that without TPMS, 75% of vehicles on the road have at least one tire underinflated by 3 psi (20 kPa) or more.

Safety Benefits:Properly inflated tires can reduce the risk of blowouts, shorten braking distances, decrease the likelihood of skidding on wet surfaces, and enhance overall vehicle handling. For TPMS, the primary task of detection is to prevent blowouts. Underinflated tires heat up faster and cannot support their specified load. This leads to excessive tire flexing, resulting in tread separation and blowouts. Ignoring the impact of road damage on tires, they naturally lose air at a rate of 1 psi (6.9 kPa) per month, with 85% of pressure loss occurring through slow leaks.

Economic benefits:In addition to safety benefits, maintaining proper tire pressure undoubtedly carries economic considerations. European standards take into account the fuel economy provided by proper tire pressure. However, increased tire wear and abnormal tire wear caused by improper pressure also contribute to the ownership costs for drivers. The commercial freight industry relies on high fuel economy to reduce costs, demonstrating the economic benefits of proper tire pressure. Tests conducted by Goodyear Tire & Rubber Company indicate that 15% underinflation in car and trailer tires can shorten tire lifespan by 8% compared to expectations and reduce fuel efficiency by 2.5% MPG.

Tire Pressure Sensor:

Market Overview of Tire Pressure Sensor Systems: The Tire Pressure Sensor is installed inside automobile tires, enabling real-time monitoring of tire pressure and temperature. It utilizes RF technology to transmit specific communication information to the receiver inside the vehicle. Drivers can thus be informed about the current condition of their tires, reducing the likelihood of accidents. In addition to enhancing safety, TPMS on average can improve fuel economy by around 2%, reducing carbon dioxide emissions, saving fuel consumption, and promoting environmental protection. These factors contribute significantly to the legislative efforts of various countries to mandate TPMS as a standard feature in vehicles.

TPMS TOOL:

CRT 5011E

Product Introduction:

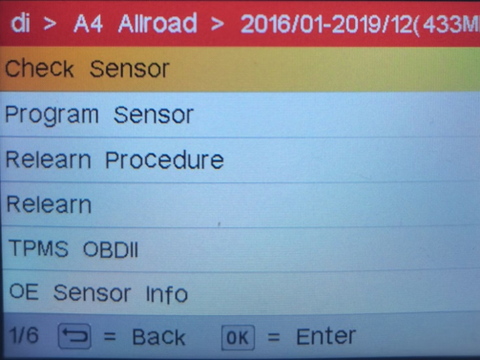

The CRT 5011E Tire Pressure Detection System Activation Diagnostic Tool is a professional tire pressure diagnostic tool that integrates TPMS sensor activation and programming, ECU diagnostics, and learning functions. It activates and reads tire pressure information through low-frequency transmission and high-frequency reception signals, and utilizes the OBD interface to read and learn tire pressure modules.

Features:

-

Supports solving tire pressure issues for over 98% of vehicles on the market.

-

Can activate all 315/433MHz tire pressure sensors and program VDO tire pressure sensors.

-

Can read tire pressure data, including pressure and tire temperature.

-

Can perform tire pressure matching learning via the OBD interface.

-

Can diagnose tire pressure faults, including reading and clearing fault codes.

-

Supports unlimited programming of VDO sensors, suitable for different vehicle models.

-

OBD detection function.

-

Closed-loop system for stability and reliability.

-

High-brightness 3.5-inch color display screen, providing clear and stable display with a wide viewing angle.

-

The product is equipped with user-friendly shortcut keys, effectively improving usability efficiency.

CRT 5011 V2.0

Product Introduction: The CRT5011 V2.0 is still under development and is planned to be launched in early June.

Compared to other ARM products like the CRT511, the CRT5011 V2.0 offers the following advantages:

-

5-inch screen for clearer data display and easier operation with touchscreen functionality.

-

2+32GB operating storage space for smoother performance.

-

6000mAh battery capacity for longer usage time.

-

Wifi one-key upgrade, eliminating the need for computer connections or memory card insertion for upgrades, making the process simpler.

-

OE number query allows for accurate model menu positioning based on sensor part numbers.

-

Includes 12 commonly used special functions, suitable for basic daily maintenance.

-

Supports diagnosis report generation and sharing, facilitating historical diagnosis queries and after-sales service maintenance.

-

Supports data feedback for timely optimization and targeted version updates, helping customers promptly address vehicle issues.

-

Unit and ID options are directly presented in the vehicle model function interface for easier settings.

-

Supports maintenance database access, allowing customers to search for tire pressure-related repair cases, testing techniques, common problem resolutions, etc.

i-TPMS

Product Introduction: The i-TPMS activates and reads tire pressure information through low-frequency transmission and high-frequency reception signals. The i-TPMS tire pressure gun needs to be used with the comprehensive diagnostic equipment from Launch Company to perform tire pressure activation, programming, diagnosis, and learning functions, or it can be paired with the i-TPMS mobile app for tire pressure activation, programming, and ID copying functions.

Features:

-

Supports solving tire pressure issues for over 98% of vehicles on the market.

-

When paired with the i-TPMS app or Launch diagnostic equipment, it can activate all 315/433MHz tire pressure sensors and program Launch tire pressure sensors.

-

When paired with the i-TPMS app or Launch diagnostic equipment, it can read tire pressure data, including pressure and tire temperature.

-

When paired with Launch diagnostic equipment, tire pressure matching learning can be performed through the OBD interface.

-

When paired with Launch diagnostic equipment, tire pressure fault diagnosis can be conducted, including reading and clearing fault codes.

-

Supports unlimited programming of Launch sensors, suitable for different vehicle models.

-

When paired with Launch diagnostic equipment, OBD detection functionality is available.

-

Convenient to carry and easy to operate.

The i-TPMS tire pressure detection handheld terminal can be used in conjunction with Launch diagnostic equipment.By connecting to the diagnostic device via Bluetooth, i-TPMS enables operations such as sensor activation, programming, ECU diagnosis, and learning.

The i-TPMS tire pressure detection handheld terminal can be paired with the Launch Tire Pressure i-TPMS App. By connecting to the i-TPMS App via Bluetooth, i-TPMS enables operations such as sensor activation and programming.

Tire Pressure Matching Common Techniques

I. Tire Pressure Sensor Activation Tips

-

Sensor activation is a direct way to determine the condition of sensors in tires. Before activation, choose the correct vehicle model and year menu based on the vehicle model year. During activation, the tire pressure tool should be vertically attached to the tire position. The CRT501 is used as an example in the picture, but other tire pressure tools have similar activation methods.

II. Tire Pressure Sensor Programming Tips

-

Tire pressure sensor programming function can only be performed on Launch sensors. It cannot be used for sensors of other brands or original factory products.

-

When replacing Launch sensors, it is recommended to program the sensors first, then install them onto the tires.

-

If the tire pressure sensors are not installed on the tires during programming, place the sensors in front of the device. If they are already installed, ensure that the device is vertically attached to the tire (sensor activation position) during programming. If the sensors cannot be detected during programming, deflate the tires to 0KPA before proceeding.

III. Tire Menu Selection Tips

-

Menu selection includes vehicle series, model, and year. Issues with menu selection mainly arise from choosing the correct year. If there is only one menu with the original vehicle year, select it directly. If there are multiple overlapping year menus, locate the menu based on the OE number of the original vehicle sensor. The OE number acts as the sensor's identity and protocol information. When selecting the year menu, it is essential to match this information. The OE number of the sensor can be found on the sensor itself.

IV. How to Determine if a Vehicle is Equipped with Aftermarket Tire Pressure Sensors

-

Aftermarket tire pressure installation mainly includes original factory protocol installation and non-original factory protocol installation.

-

Non-original factory protocol tire pressure installation involves installing custom protocol sensors from the manufacturer. For such tire pressure sensors, we cannot perform replacements. Our replacements mainly revolve around the original factory protocol. Non-original factory tire pressure installations mainly manifest in the following ways: A. External tire pressure display or replacement of a new central control screen for display. B. Tire pressure sensors have tire position labels affixed on them.

-

Original factory protocol tire pressure installation, as the name suggests, follows the vehicle's original protocol. This type of tire pressure generally requires using diagnostic equipment to set the code and enable tire pressure display. Since this type of installation follows the original vehicle protocol, our sensors can be replaced. The most common examples are tire pressure installations for BMW and Mercedes-Benz vehicles.

V. Tire Pressure Fault Detection Process

-

Tire pressure fault codes mainly include tire pressure sensor faults, tire pressure module faults, tire pressure receiver antenna anomalies, line issues, and interference issues.

-

Tire pressure fault resolution process: Check the instrument panel or central control for abnormal tire pressure display → Activate sensors → Program and replace sensors → Tire pressure sensor learning → Read ECU ID.

-

Tire pressure sensor faults: These faults are relatively easy to identify. If one, two, or three out of the four displayed tire pressures on the vehicle are abnormal, it can be generally concluded as a tire pressure sensor fault code. Use our equipment to activate the tire pressure sensors inside the tires to confirm which ones are abnormal. Sensors that cannot be activated or are difficult to activate due to low voltage are considered faulty. Replace them with Launch sensors, perform sensor learning, and note that Launch sensors need to be programmed before installation.

-

Tire pressure module faults and line faults: When the module and line faults occur, the equipment may experience communication failures during system entry, or X431 scanning systems may fail to detect the tire pressure system, or there may be no communication fault codes from the on-site tire pressure module. If these issues arise, use circuit diagrams to detect tire pressure module and line abnormalities.

-

Tire pressure receiver antenna faults: While most vehicle models now integrate tire pressure receiver antennas into the tire pressure modules, there are still a few models with separate external tire pressure antennas. Customers need to consult the vehicle's circuit diagrams to determine this. In the event of a tire pressure receiver antenna fault, all four tires on the vehicle will have no tire pressure information, and reading the fault codes will show all four tire pressure sensors have no signal codes (some vehicles may also directly report module faults). In this case, use circuit diagrams to detect tire pressure antenna issues. (Note: If all four sensors fail to display tire pressure and the tire pressure warning light is on, try activating the tire pressure sensors first. If all four cannot be activated or have difficulty activating, displaying low voltage, it is highly probable that there is a sensor problem. Simply replace the sensors. However, specific circumstances still require customers to diagnose and handle based on the actual performance of the vehicle.)

-

Interference issues: Interference mainly occurs when the vehicle is equipped with devices such as dashcams, Bluetooth devices, or GPS locators. Symptoms mainly include all four tire pressures not displaying or several not displaying. Meanwhile, all four original vehicle sensors can be activated, and their activation information is normal. If this issue arises, investigate vehicle interference problems. If the interference problem cannot be confirmed, try swapping the tires between the abnormal and normal positions and then conduct a road test to observe where the fault occurs. If the fault remains in the original position, it indicates that there is interference in the vehicle causing tire pressure abnormalities. Conduct further investigation into the source of interference.